CNC Machining Materials

We can generate instant machining quotes for 50+ metals and plastics.

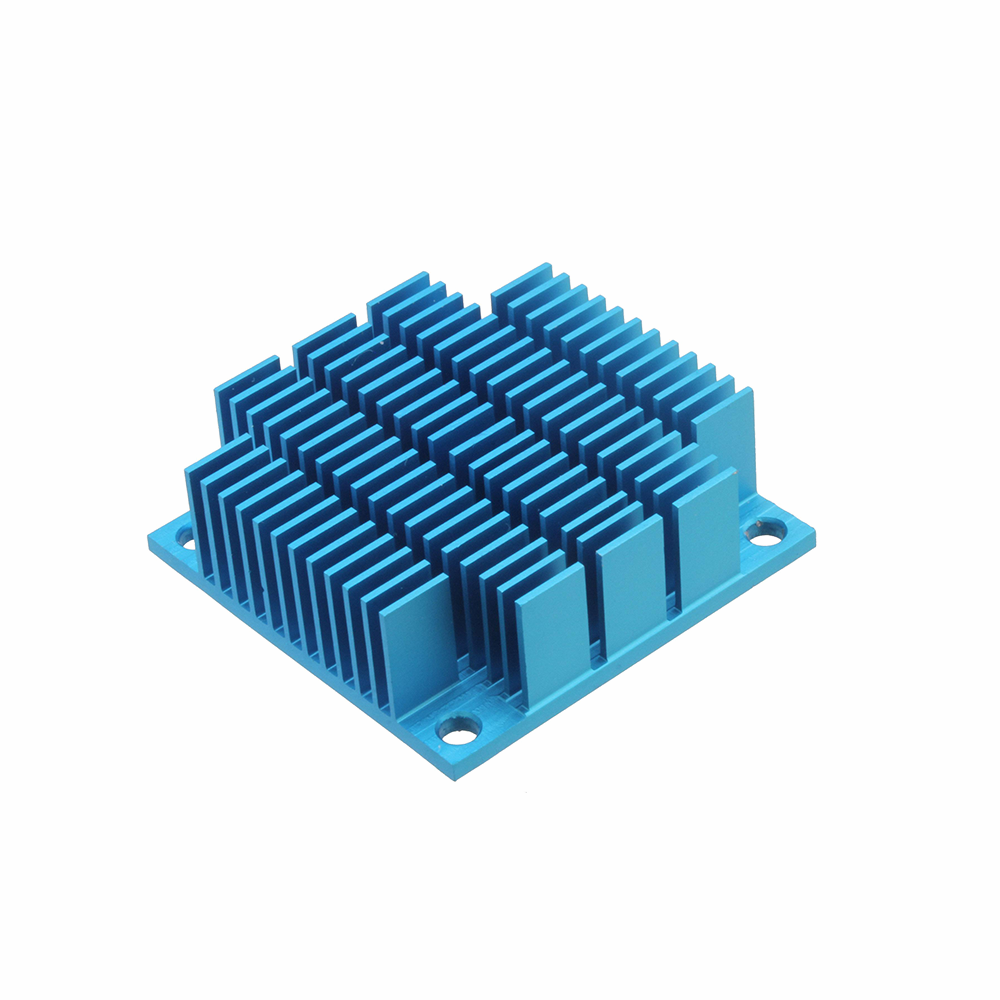

Aluminum 7075-T7351 | 3.4365 | 76528 | AlZn5.5MgCuAluminum 6061-T651

| 3.3211 | 65028 | AlMg1SiCuAluminum 7075-T651 | 3.4365 | 76528 | AlZn5.5MgCuAluminum 6082-T651 | 3.2315 | 64430 | AlSi1MgMnAluminum 6060 | 3.3206 | AlMgSiAluminum 5052 | EN AW-5052 | 3.3523 | AlMg2,5Aluminum 2017A | 3.1325 | 24530 | AlCu4MgSiAluminum 2014 | 3.1255 | 24345 | AlCu4SiMgAluminum 6063 | EN AW-6063 | 62400| AlMg0,7SiAluminum 7050 | EN AW-7050 | 3.4144| AlZn6CuMgZrAluminum 2024-T351 | 3.1355 | 24530 | AlCu4Mg1Aluminum MIC6Aluminum 7075-T6 | 3.4365 | 76528 | AlZn5,5MgCuAluminum 5083-H111 | 3.3547 | 54300| AlMg4.5Mn0.7Aluminum 6082 | 3.2315 | 64430| AlSi1MgMnAluminum 6061-T6 | 3.3211| 65028| AlMg1SiCu

Stainless steel 416 | 1.4005 | X12CrS13Stainless steel 15-5 | 1.4545 | X5CrNiCu15-5Stainless steel 301 | 1.4310 | X10CrNi18-8

Stainless steel 430 | 1.4016 | X6Cr17Stainless steel 440C | 1.4125 | X105CrMo17Stainless steel 420 | 1.4028 | X30Cr13Stainless steel 304/304L | 1.4301/1.4307 | X5CrNi18-10/X2CrNi18-9Stainless steel 2205 Duplex | 1.4462 | 2205 | X2CrNiMoN 22-5-3Stainless Steel 17-4 PH | 1.4542 | X5CrNiCuNb16-4 – Annealed stateStainless steel 303 | 1.4305 | X8CrNiS18-9Stainless steel 316/316L | 1.4401/1.4404 | X5CrNiMo17-12-2/X2CrNiMo17-12-2

Alloy steel 1.7131 | 16MnCr5Alloy steel 1215 | EN1A | 1.0715Alloy steel 4340 | 1.6511 | 36CrNiMo4 | EN24Alloy steel 4140 | 1.7225 | EN19 | 42CrMo4

Tool steel A3 – Annealed stateTool steel H13 | 1.2344 | X40CrMoV5-1 – Annealed stateTool steel S7 | 1.2355 | 50CrMoV13-15 – Annealed stateTool steel O1 | 1.2510 | 100MnCrW4 – Annealed stateTool steel A2 | 1.2363 | X100CrMoV5-1- Annealed stateTool steel D2 | 1.2379 | X153CrMoV12-1 – Annealed state

Brass Cz121 | C38500 | 2.0401 | CuZn39Pb3Brass C360 | 2.0375 | CuZn36Pb3 | 319 grade 2

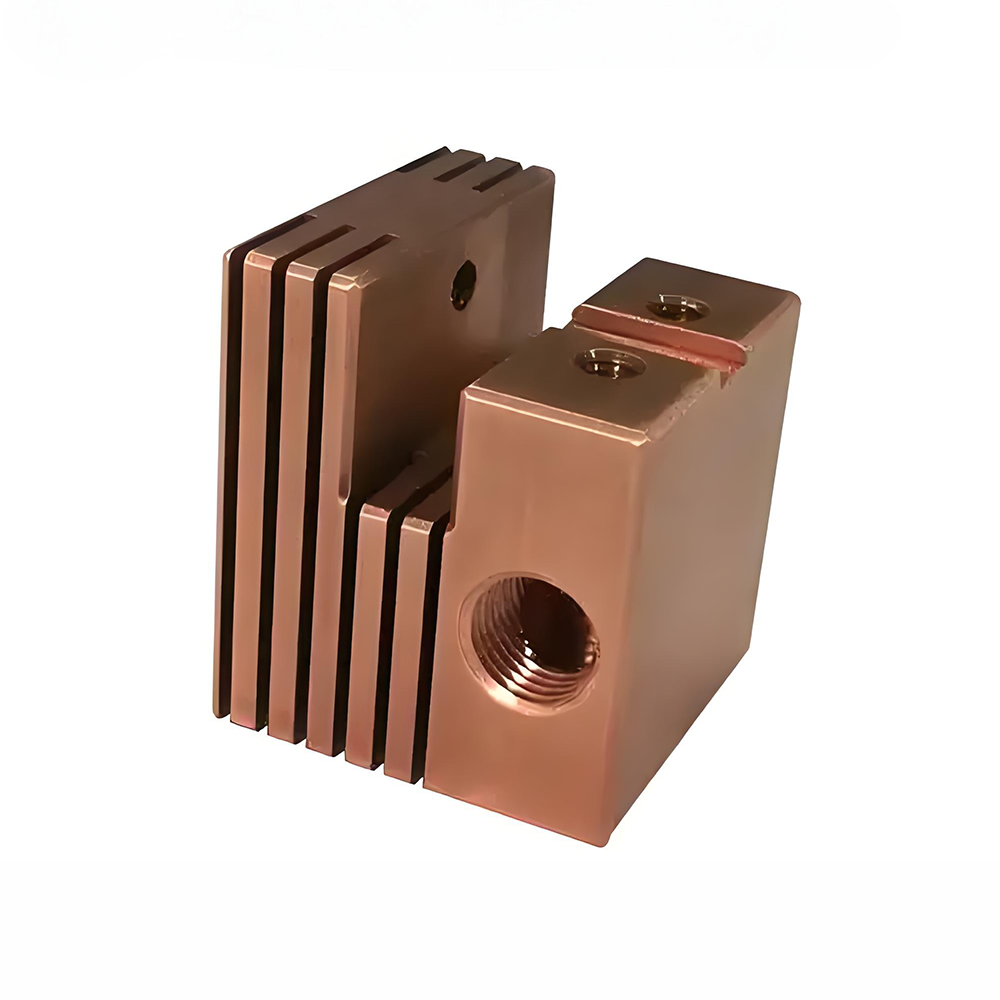

Copper C101 | CU OFECopper C110 | CU ETP

Titanium Grade 5 | 3.7164 | Ti6Al4VTitanium Grade 2 | 3.7035Titanium Grade 1 | 3.7025

AZ61A | AZ91D | M1191T | M12331

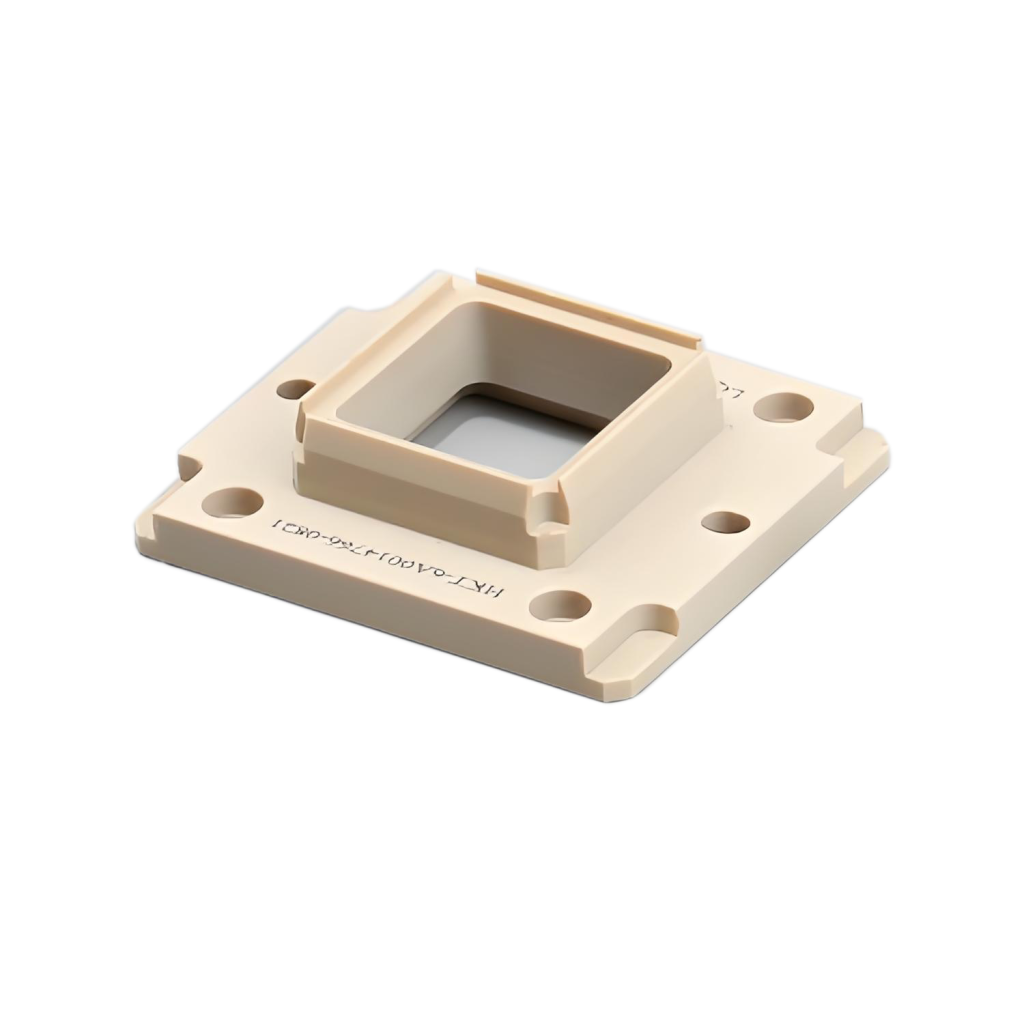

POM is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability.

Acetal Copolymer (POM-C), Acetal Homopolymer (POM-H)

Polyamide (PA) is an engineering thermoplastic with excellent mechanical properties and high chemical and abrasion resistance.

Nylon 6, Nylon 6 30% Glass Filled, Nylon 6/6 30% Glass Filled

PPSU offers exceptional hydrolytic stability, and toughness superior to other commercially-available, high-temperature engineering resins, inherently flame retardant, excellent thermal stability and good electrical properties.

Common thermoplastic with all-around good mechanical properties, excellent impact strength, good heat resistance and good machinability.

Engineering thermoplastic with excellent chemical and thermal resistance and the lowest coefficient of friction of any know solid.

Thermoplastic with high toughness, excellent impact strength and good machinability, optically transparent.

Transparent rigid plastic often used as a substitute for glass.

The third most used plastic with all-around good mechanical properties, excellent chemical and weather resistance and good toughness.

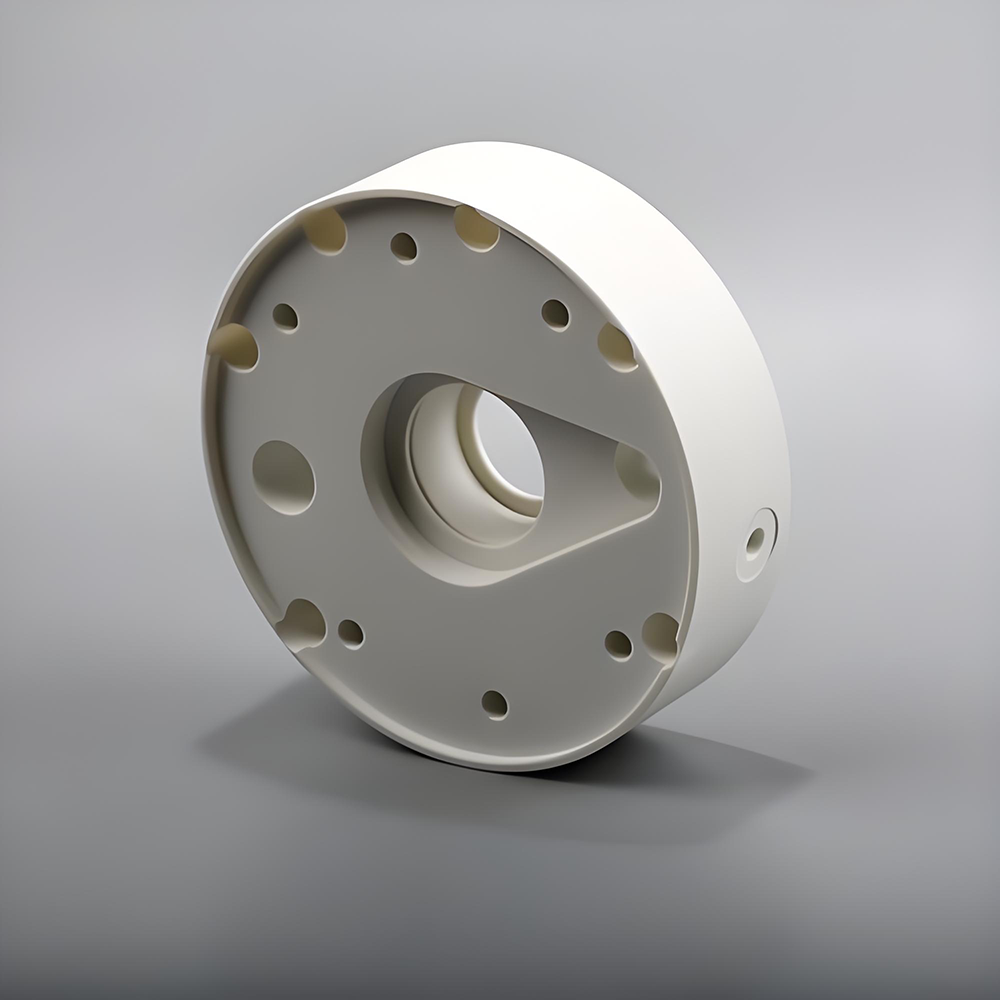

Start Your Project in 4 Steps

Upload Files

Upload your design drawings and 3D models to our quote page, and get instant quotations within 24H.

STEP 1

Quotation

Get best prices offer, discussing technical details from drawings to real objects in precision, high quality.

STEP 2

Production

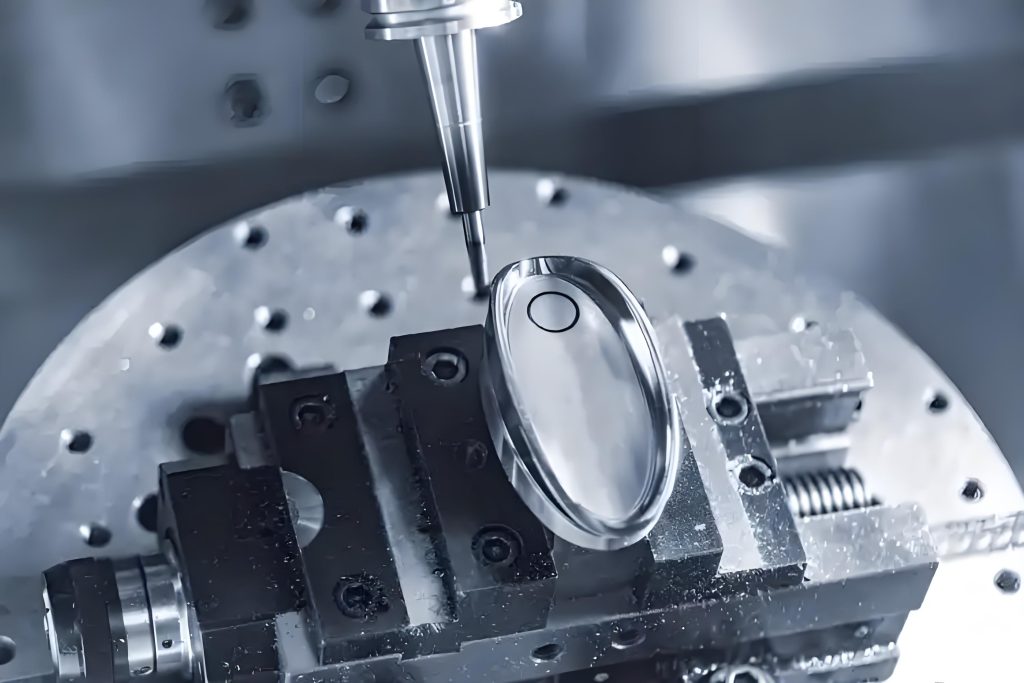

Use advanced machines shaping material to preccision workpiece. Full range of heat Treating, machining, polishing…

STEP 3

Door to Door Shipment

Door to door prompt shipment via reliable logistics, bringing your parts on desktop.

STEP 4

Make your Ideas Real Now!

Metals for sheet metal services

We can generate instant machining quotes for 50+ metals and plastics.

Moderate strength and good fatigue resistance. Excellent thermal and electrical conductivity.

Automotive parts, marine components, electronic chassis

Excellent corrosion resistance, good formability and weldability.

Automotive panels and components, marine components

High electrical conductivity, thermal conductivity, and corrosion resistance.

Electrical wiring, plumbing, heat exchangers

Excellent mechanical properties and good machinability. Resistant to most environments and corrosive media.

Food processing equipment, kitchen appliances, architectural trim

Similar mechanical properties to 304, with higher corrosion and chemical resistance.

Chemical processing equipment, medical implants, marine hardware

Good machinability, weldability, toughness, strength. Susceptible to corrosion.

Screws, nuts, bolts, gears, automotive componentsChemical processing equipment, medical implants, marine hardware

Why Choose Us?

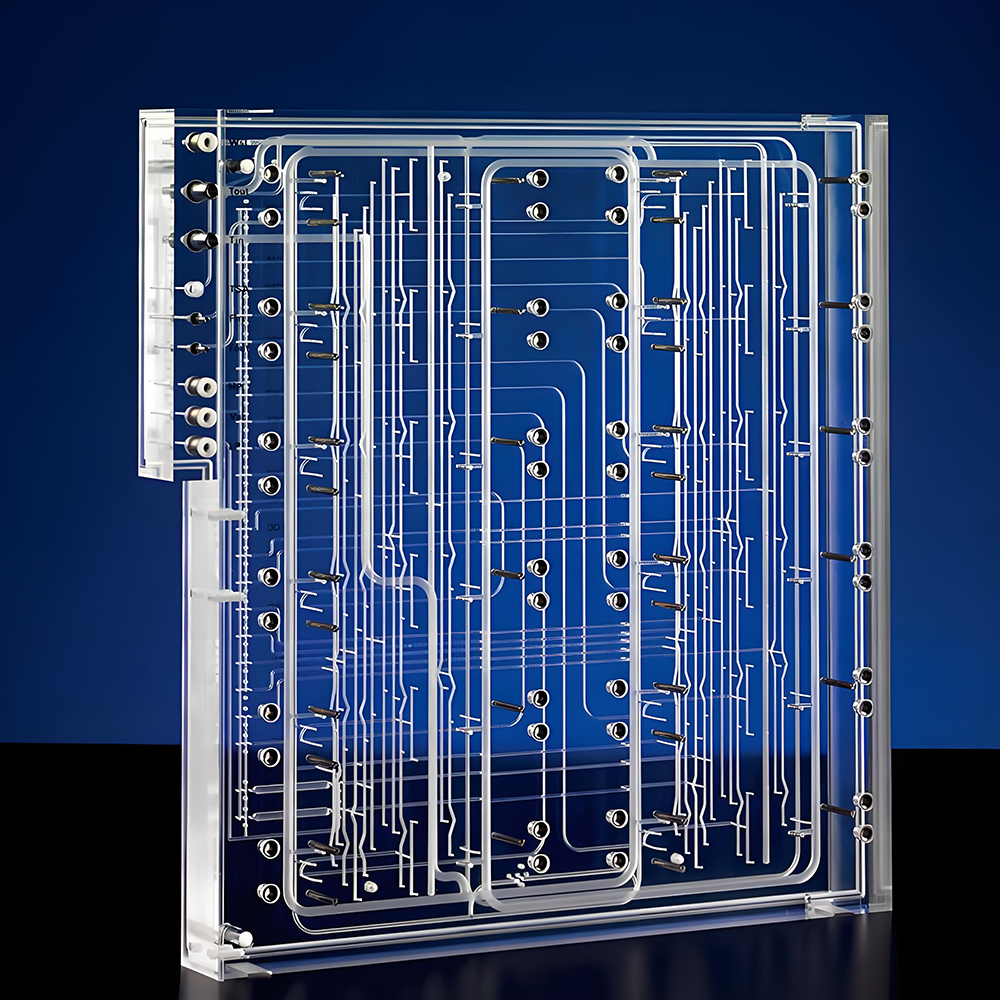

CNC machining is fast, accurate, and versatile. No other manufacturing solution produces end-use parts in any volume without the need to invest in hard tooling or expensive set-ups.

What raw materials can I use with CNC machining?

Almost any rigid solid can be machined, including mild and stainless steels, aluminum, brass, copper, magnesium, titanium, and many types of engineering plastics. Check out our list of frequently used materials.

What tolerances can I achieve with CNC machining?

Our standard tolerances are 10 microns (0.01 millimeters or 0.00039 inches), which is suitable for the majority of commercial and industrial applications. Consult with us if you need closer tolerances for special projects.

Choosing SYRAIndustries FAQ

Want to learn more?