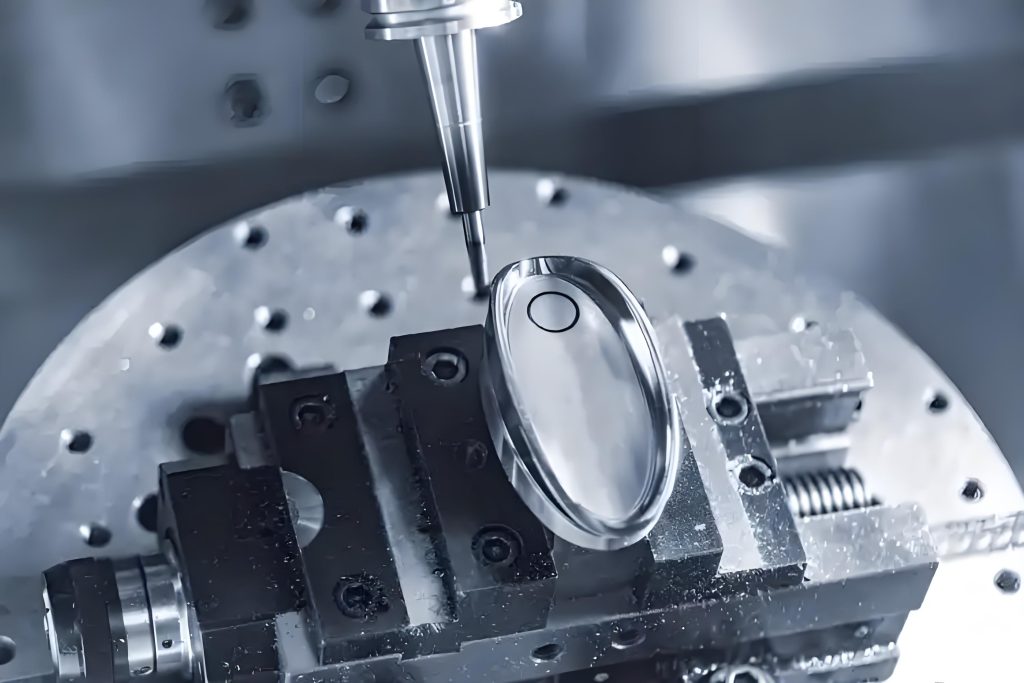

Testing and Inspection

Careful measurement, inspection and testing are necessary to ensure the conformance of your parts.

What is special our inspection processes?

Careful measurement, inspection and testing are necessary to ensure the conformance of your parts. We perform multiple inspections at every step of the product development journey, from incoming material verification to final 3D scanning. You will receive complete digital files and Certificates of Compliance so you can meet your own regulatory and performance goals.

An Experts Team with Unparalleled Experience

Quality inspection relies not only upon using advanced digital equipment but also having highly trained personnel with years of experience. As parts become more complex and tolerances more demanding for advanced applications, precision measurements conducted by professionals are the only way to ensure perfection.

Inspections and Review for Every Stage of Production

To ensure quality from start to finish, Star Rapid provides the following inspection and review services:

- Extensive incoming materials verification

- Design for manufacturing reviews for all quotes provided

- Contract reviews upon receipt of POs

- First article and in-process inspections

- Final inspections and testing with reports and certifications as required

Choosing SYRAIndustries FAQ

Want to learn more?

Some call them customers. We call them partners.

ISO certifications

Thanks to our highly vetted supplier network and ISO 9001-certified Quality Management System, it’s always possible to have your parts manufactured with industry-specific certifications.

How we assess the quality of our suppliers

We have a comprehensive method for selecting, onboarding and tracking the performance of every supplier in our manufacturing partner (MP) network.

Various Inspection Facilities

We use a variety of equipment and tools, inspecting the appearance, function, and performance of the product, ensuring meticulous inspection to deliver parts that meet precision and high reliability.