Sheet Metal Services

Sheet metal cutting and bending service. Upload your parts, get a free instant quote and go into production in less than 5 minutes.

Sheet Metal Collaborating Capabilities

Our network of manufacturing partners gives you easy access to sheet metal fabrication capabilities to serve all your manufacturing needs.

Laser cutting

This manufacturing process uses a high-power laser beam to cut a material sheet.

- Allowable sheet thickness: 1-6mm (depending on material)

Bending

This manufacturing process uses dies to produce a U-shape, V-shape or channel shape along a straight axis in ductile materials.

- Allowable sheet thickness: 1-6mm (depending on material)

Sheet Metal Materials and Tolerance

We can generate instant machining quotes for 50+ metals and plastics.

Start Your Project in 4 Steps

Upload Files

Upload your design drawings and 3D models to our quote page, and get instant quotations within 24H.

STEP 1

Quotation

Get best prices offer, discussing technical details from drawings to real objects in precision, high quality.

STEP 2

Production

Use advanced machines shaping material to preccision workpiece. Full range of heat Treating, machining, polishing…

STEP 3

Door to Door Shipment

Door to door prompt shipment via reliable logistics, bringing your parts on desktop.

STEP 4

Make your Ideas Real Now!

Advantages of sheet metal services

A general snapshot of the Advantages of sheet metal fabrication having a more complete understanding of whether a particular sheet metal fabrication process is suitable for your application, more research into each individual process is needed.

Fast affordable for production or prototyping

Fabrication can quickly produce prototype parts with the same precision and speed that produce in production. It can also be easily customized, so if the first design doesn’t work as planned – no sweat – the very next part can be adjusted.

Vast number of techniques and materials

These varying techniques allow make it possible to create relatively complex parts by cutting flat sheets, bending parts into place and adding holes, slots, and notches cut in all the right places.

High strength to weight ratio

Sheet metal can be useful when trying to keep a project lightweight. Adding bends to sheet metal increases the structure’s strength tremendously because it increases the stiffness in multiple axes.

precision sheet metal fabrication

Precision sheet metal fabrication refers to some of the exact same methods and techniques as “non-precision” but to a closer degree of tolerance.

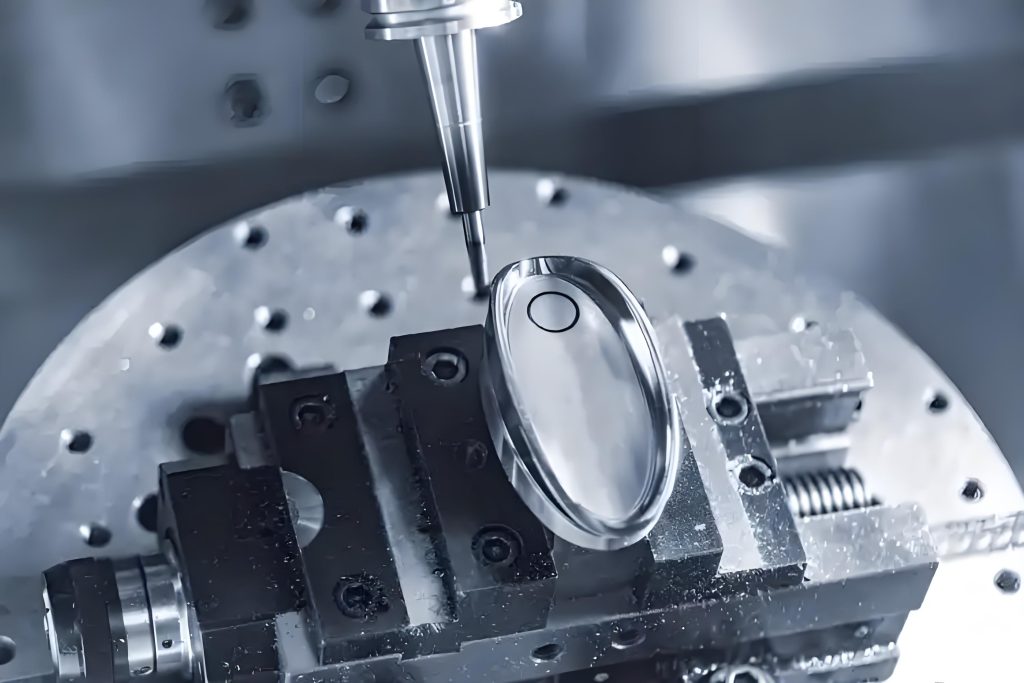

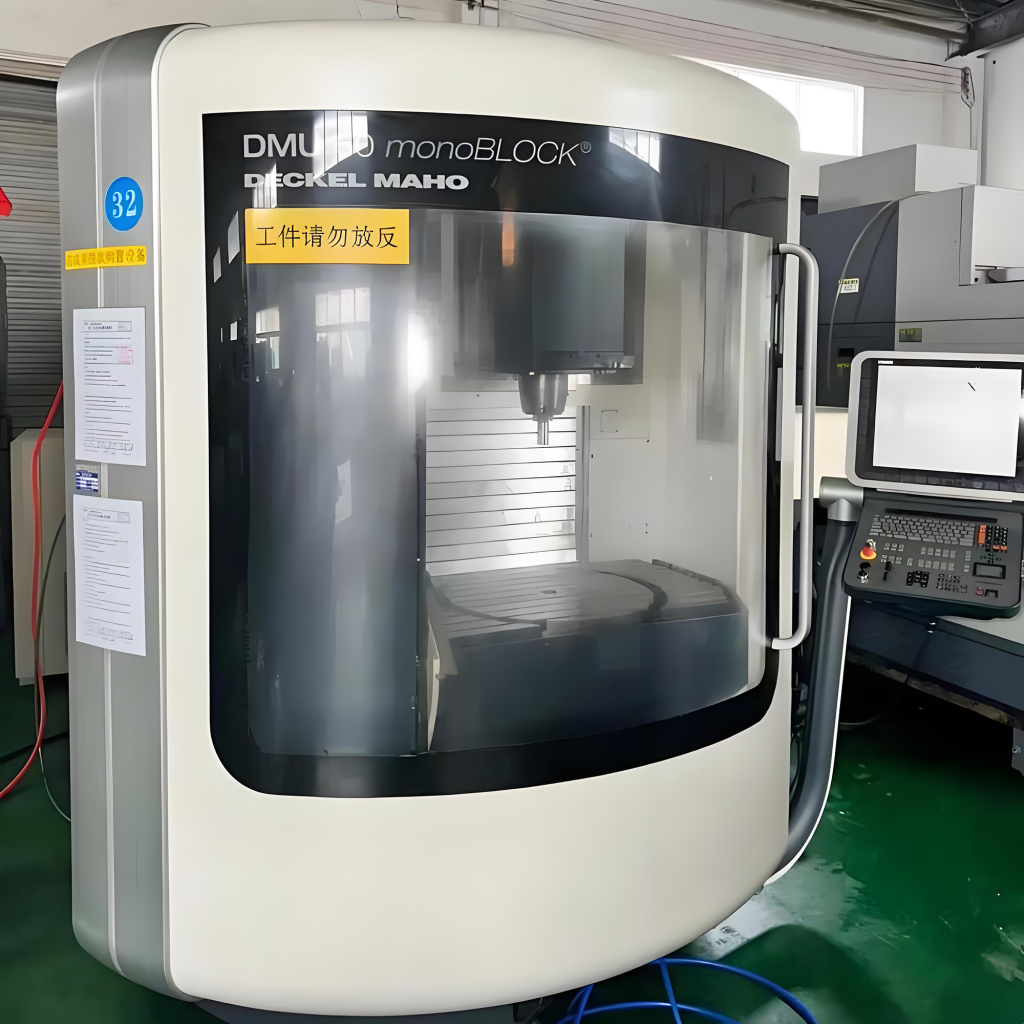

Our Sheet Metal Service Capabilities

If you are looking for reliable precision manufacturer for custom metal machined components, SYRAIndustries will be an ideal solution for you. There are cutting-edge machines in our company. We are confident in capabilities regardless of simple or complex geometrical parts with tight tolerance and high precision.

SHARPE Heavy CNC Center

DMU MonoBlock

TAKISAWA CNC Lathe

JINGDIAO 3-Axis CNC Center

Hans 5-Axis CNC Center

SODICK Wired EDM

Cutting-edge Machines Workshop

CNC Turning Workshop